Automotive & Industrial Sectors

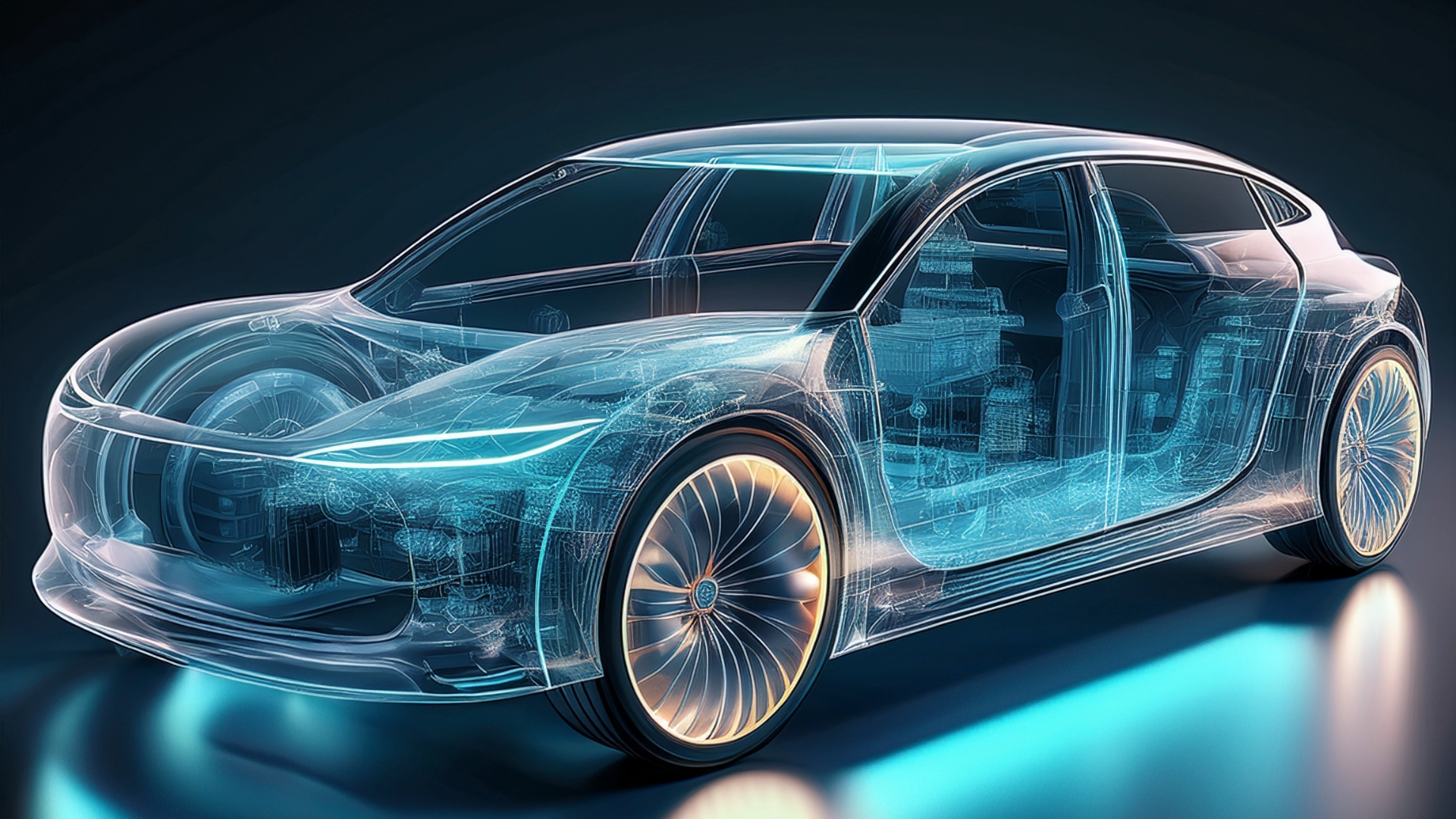

For decades, maintenance followed a predictable cycle: wait until something breaks, fix it, and hope downtime doesn’t cost too much. But in 2025, that model is quickly becoming obsolete. Enter predictive maintenance — an approach that uses sensors, data analytics, and remote monitoring to anticipate failures before they happen.

This shift is transforming customer expectations across the automotive and industrial sectors, where downtime is not just inconvenient — it’s costly and disruptive. Companies that embrace predictive maintenance are redefining what “service” really means, while platforms like Servicingpedia are giving providers and fleet owners the tools to make it happen.

What Is Predictive Maintenance? 🛠️📊

Predictive maintenance (PdM) uses IoT sensors and advanced analytics to monitor the condition of machines, vehicles, or components in real time. Instead of waiting for scheduled service or unexpected breakdowns, PdM tools trigger alerts when early warning signs appear — such as unusual vibration, temperature spikes, or component wear.

Think of it as a “health check” for machines, where data points act like vital signs, letting you act before a costly failure occurs.

Real-World Examples of Predictive Maintenance in Action 🚘🏭

- Tesla integrates predictive diagnostics into its vehicles, sending automatic alerts when parts show early signs of degradation. This minimizes roadside failures and reduces customer anxiety.

- BMW leverages connected-car systems and remote software updates, as highlighted in Hicron Software’s report, to anticipate maintenance needs and streamline after-sales services.

- Industrial OEMs (Original Equipment Manufacturers) are embedding PdM into heavy machinery. According to McKinsey, predictive service strategies can cut downtime by up to 30% and reduce maintenance costs by 20%.

Why Customers Now Expect Predictive Service 📈

In today’s always-on economy, downtime isn’t acceptable. Fleet managers, manufacturers, and even car owners expect:

- Proactivity: Issues flagged before they cause failures.

- Transparency: Clear data on what’s wrong and why.

- Reliability: Reduced risk of surprise breakdowns.

- Cost Savings: Fewer emergency repairs and more optimized part usage.

Predictive maintenance is no longer seen as a “premium add-on” — it’s quickly becoming the baseline expectation for modern service.

Challenges of Predictive Maintenance ⚠️

While powerful, predictive maintenance isn’t without obstacles:

- Data Collection & Integration: Managing millions of sensor readings is complex.

- Sensor Reliability: Faulty sensors can create false positives or missed alerts.

- Cost: Initial investment in connected devices and analytics tools.

- Bias in Data Models: Algorithms must be continually updated to remain accurate.

Companies that address these challenges with the right digital tools gain a critical competitive edge.

How Servicingpedia Supports Predictive Maintenance 🚀

At Servicingpedia, we recognize that predictive maintenance is shaping the future of services. Our platform helps providers and fleet owners by offering:

✅ Service Schedule Tracking – Never miss a required inspection or replacement.

✅ Predictive Alerts – Receive early warnings when wear-and-tear patterns emerge.

✅ Full Maintenance Logs – Centralized histories for every vehicle or machine.

✅ Analytics Modules – Monitor performance and downtime risks in real time.

By reducing surprises and downtime, Servicingpedia enables service providers to move from reactive fixes to proactive, value-driven service delivery.

Final Takeaway

Predictive maintenance is more than a technological trend — it’s a customer expectation. Automotive brands, industrial OEMs, and service providers that embrace it will save costs, improve uptime, and build stronger customer trust.

With Servicingpedia, you don’t just maintain — you predict, prevent, and perform at the next level.

📲 Ready to future-proof your service approach? Explore our predictive-maintenance modules or book a consultation with Servicingpedia today.

You explained it in such a relatable way. Well done!